Global fierce competition, congratulations on being shortlisted!

2021-02-02 13:29:50

On January 23, 2021, our corporate member Shenzhen Candor Technology Co., Ltd. received an email from the authoritative AMPP journal Materials Performance, informing Shenzhen Candor Technology Co., Ltd. that it has been shortlisted for Materials Performance 2021 "Corrosion Innovation Awards". We would like to express our heartfelt congratulations to Shenzhen Candor Technology Co., Ltd.!

It is reported that hundreds of outstanding companies from the global corrosion protection industry have applied for Materials Performance's 2021 "Corrosion Innovation Awards". According to statistics, the total number of nomination applications for these awards has reached a record high! After multiple selections, Materials Performance is pleased to announce that 40 innovative technologies have been shortlisted for this year's awards. Welcome to log in to the official website of Materials Performance to view the complete list of shortlisted innovative technology companies.

As we all know, the Materials Performance Corrosion Innovation Awards attach great importance to technological innovation in corrosion protection and the positive impact that this technology has on the entire corrosion industry. Technical content can be related to coating, lining, material design and selection, inspection and testing, modeling and risk assessment, cathodic protection, chemical treatment and anything else related to corrosion protection.

The awards aim to provide AMPP members with a platform to showcase the latest corrosion innovation technologies. A panel of corrosion protection expert judges is currently conducting the final round of scoring and the 10 final winners are expected to be informed by mid-February, with the winners expected to be recognized at the CORROSION 2021 conference from April 19 to 30, 2021.

Congratulations again to Shenzhen Candor Technology Co., Ltd. for being shortlisted for the Materials Performance 2021 Corrosion Innovation Awards for its innovative corrosion protection technology. Let us look forward to the award results together! In addition, we also expect that more and more outstanding Chinese corrosion protection companies will stand on the international corrosion protection stage and show your corrosion protection technology achievements to the world!

Brief introduction to shortlisted technologies

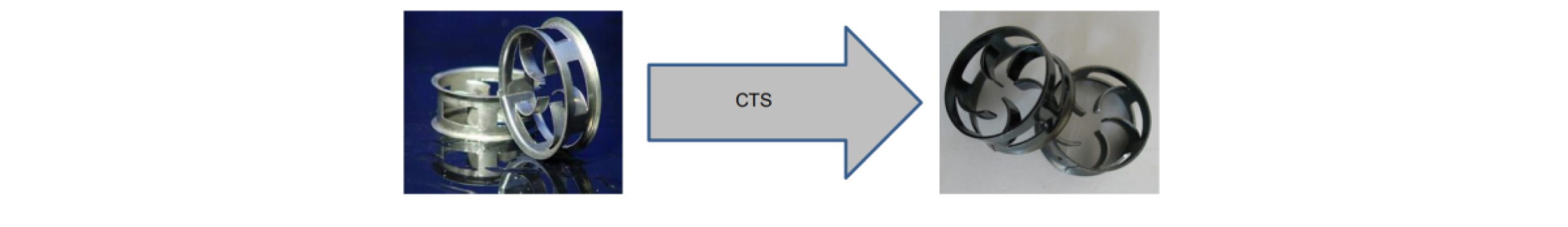

The key technology for ultra-high performance corrosion resistance and anti-coking of stainless steel surfaces in harsh environments (CTS technology) is a complete set of industrialized technologies for ultra-high performance corrosion resistance and anti-coking on stainless steel surfaces developed by the research team established by Shenzhen Candor Technology Co., Ltd., SEI, LPEC, Beijing University of Chemical Technology, and many refining and chemical companies over 26 years of endeavor.

CTS technology aims to obtain an amorphous dense film layer rich in chromium oxide that greatly improves the corrosion resistance of stainless steel, using austenitic stainless steel as the substrate, and by chemical-electrochemical method. The film layer and the substrate have an anchoring structure that allows the film layer to have a high adhesion. The thickness of the film is more than 100 times that of the natural passivation film of stainless steel. In addition, by reducing the content of Fe and Ni elements with high coking catalytic activity in the film, the surface of the film becomes an integrated corrosion-resistant and anti-coking material.

At present, CTS technology has employed in 14 types of plants under severe operating conditions such as high acid, high sulfur, and high chlorine, etc. The surface-strengthened stainless steel material’s service life can be expanded by more than 2 times, effectively slowing down coking in the high-temperature section of the vacuum tower and ensuring a stable pressure drop of the vacuum tower during the operation period with no more than 5% increasments. It greatly improves the corrosion resistance and coking resistance of stainless steel, allowing low-grade materials to replace high-grade materials in terms of corrosion resistance. It also improves the process effects of refining equipment and creates huge economic benefits and social value. This technology is at the international leading level in the field of corrosion resistance and anti-coking of stainless steel materials for petrochemical applications, as a "Created in China" technology for surface strengthening of stainless steel materials.